Specific Gravity (Density)

ASTM D

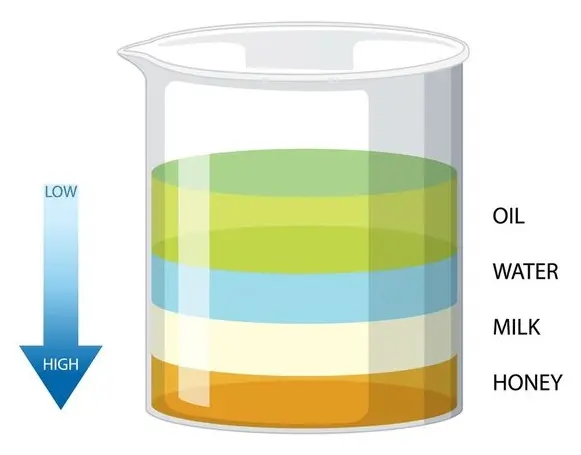

What is Specific Gravity? Specific gravity (SG) is the ratio of the density of a substance to the density of water at a specified temperature. For transformer oil, this property helps in understanding the oil’s composition and its ability to suspend contaminants like water and particulate matter.

Importance of Specific Gravity in Transformer Oil

- Contaminant Detection: Specific gravity can indicate the presence of contaminants. For instance, if the specific gravity is higher than usual, it may suggest contamination by heavier substances.

- Water Content: Since water has a specific gravity of 1.0, the specific gravity of the oil can help determine the presence and distribution of water within the oil. Water can significantly reduce the dielectric strength of the oil, leading to potential failures.

- Heat Transfer Efficiency: The specific gravity affects the oil’s ability to transfer heat. Oils with lower specific gravity generally have better heat transfer properties.

The specific gravity of transformer oil is typically measured using a hydrometer at a reference temperature.

Equipment Needed

- Hydrometer: A device that measures the density of liquids.

- Thermometer: To measure the temperature of the oil sample.

- Graduated Cylinder or Test Jar: To hold the oil sample during testing.

Procedure

- Sample Collection:

- Collect the oil sample from the transformer. If the specific gravity of the oil is less than 1 (which is typical), take the sample from the bottom of the transformer1.

Temperature Adjustment:

- Measure the temperature of the oil sample using a thermometer.

- The specific gravity readings are temperature-dependent, so it’s important to note the temperature at which the measurement is taken.

Hydrometer Calibration:

- Ensure the hydrometer is clean and calibrated. Calibration should be done at a reference temperature, usually 15°C or 20°C, depending on the standard being followed.

Measurement:

- Pour the oil sample into the graduated cylinder or test jar.

- Gently lower the hydrometer into the oil sample, ensuring it does not touch the sides of the container.

- Allow the hydrometer to settle and float freely. The point at which the surface of the oil touches the scale of the hydrometer is the specific gravity reading.

Reading and Recording:

- Read the specific gravity value at the point where the oil surface meets the hydrometer scale.

- Record the specific gravity and the temperature of the oil sample.

Temperature Correction:

- If the measurement is taken at a temperature different from the reference temperature, apply a temperature correction factor to adjust the specific gravity reading to the reference temperature. This correction factor can be found in standard tables or provided by the hydrometer manufacturer.

Interpreting Results

- Normal Range: For new transformer oil, the specific gravity typically ranges from 0.84 to 0.91.

- High Specific Gravity: May indicate contamination with heavier substances or degradation products.

- Low Specific Gravity: Could suggest the presence of lighter hydrocarbons or other contaminants.

Applications

- Maintenance: Regular monitoring of specific gravity helps in early detection of oil degradation and contamination.

- Performance Optimization: Ensuring the oil maintains its specific gravity within the optimal range helps in maintaining the transformer’s efficiency and reliability.

- Safety: Properly maintained oil with the correct specific gravity reduces the risk of electrical failures and fire hazards.

Specific gravity analysis is a vital part of transformer oil testing. It provides insights into the oil’s condition and helps in maintaining the transformer’s performance and safety. Regular testing and monitoring can prevent costly failures and extend the life of the transformer.