Moisture Analysis

ASTM D6304

Standard Test Method for

Determination of Water in Petroleum Products, Lubricating

Oils, and Additives by Coulometric Karl Fischer Titration

Moisture in transformer oil can come from several sources, each contributing to the overall water content in the system. Here are some common sources:

- Atmospheric Humidity: Moisture from the surrounding air can enter the transformer, especially if there are leaks or if the transformer is not properly sealed.

- Leaks and Seals: Poorly maintained or damaged seals and gaskets can allow water to seep into the transformer oil.

- Cellulose Insulation Degradation: The paper insulation used in transformers can degrade over time, releasing water as a byproduct of this process.

- Oil Contamination: Contaminated oil, either from improper handling or storage, can introduce moisture into the transformer.

- Breathers and Conservators: Breathers are designed to filter out moisture from the air entering the transformer. If they are not functioning correctly or are saturated, they can allow moisture to enter the oil.

- Maintenance Activities: During maintenance, if proper precautions are not taken, moisture can be introduced into the transformer oil.

- Condensation: Temperature fluctuations can cause condensation inside the transformer, leading to increased moisture levels.

Regular monitoring and maintenance are essential to identify and mitigate these sources of moisture, ensuring the longevity and reliability of the transformer.

High moisture content in transformer oil can have several detrimental effects:

- Reduced Dielectric Strength: Moisture lowers the dielectric strength of the oil, increasing the risk of electrical discharges and flashovers.

- Accelerated Aging: Water accelerates the aging process of both the oil and the cellulose insulation, leading to a shorter transformer lifespan.

- Corrosion: Moisture can cause corrosion of metal components within the transformer, further compromising its integrity.

- Increased Risk of Failure: The presence of water increases the likelihood of dielectric breakdown, leading to potential transformer failures.

- Decreased Efficiency: Moisture reduces the efficiency of the transformer by impairing its insulating properties and increasing energy losses.

- Maintenance and Repair Costs: High moisture levels necessitate more frequent maintenance and can lead to costly repairs or replacements.

Various standards and guidelines provide recommendations for acceptable moisture levels in transformer oil. For instance, the IEEE C57.106 and IEC 60422:2013 guides recommend regular monitoring and maintenance to ensure moisture levels remain within safe limits. Generally, a moisture content of less than 35 ppm is considered acceptable for mineral oil.

The frequency of moisture analysis for transformers can depend on several factors, including the transformer’s age, operating conditions, and criticality. However, here are some general guidelines:

- New Transformers: For new transformers, it’s advisable to perform moisture analysis during commissioning and then periodically during the first year of operation to establish a baseline.

- Routine Monitoring: For most transformers, moisture analysis should be conducted at least once a year as part of regular maintenance. This helps in early detection of any issues and ensures the transformer operates efficiently.

- Critical Transformers: For transformers that are critical to operations or those operating under harsh conditions, more frequent monitoring may be necessary. Quarterly or even monthly checks might be warranted to ensure reliability.

- Older Transformers: As transformers age, the insulation materials can degrade, leading to increased moisture levels. For older transformers, increasing the frequency of moisture analysis to twice a year or more can help in managing the risks associated with aging equipment.

- After Repairs or Maintenance: Any time a transformer undergoes significant repairs or maintenance, it’s a good practice to perform moisture analysis to ensure no moisture has been introduced during the process.

- Abnormal Conditions: If there are signs of abnormal operation, such as unusual temperature rises, changes in oil color, or unexpected electrical behavior, immediate moisture analysis should be conducted to diagnose potential issues.

To determining the water content in transformer oil, the widely used analytical method Karl Fischer titration. It was developed by the German chemist Karl Fischer in 1935. This method is highly valued for its accuracy and efficiency in measuring trace amounts of water. Here’s a detailed look at how it works:

Principle

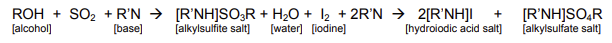

Karl Fischer titration is based on a chemical reaction between iodine and sulfur dioxide in the presence of water. The reaction can be represented as:

In this reaction, the alcohol reacts with sulfur dioxide (SO2

) and base to form an intermediate alkylsulfite salt, which

is then oxidized by iodine to an alkylsulfate salt. This oxidation reaction consumes water.

The reactive alcohol is typically methanol or 2-(2-Ethoxyethoxy)ethanol, also known as diethylene

glycol monoethyl ether (DEGEE), or another suitable alcohol.

Classic Karl Fisher reagents contained pyridine, a noxious carcinogen, as the base. The reagents most

frequently used today are pyridine-free and contain imidazole or primary amines instead.

Types of Karl Fischer Titration

There are two main types of Karl Fischer titration:

- Volumetric Titration: This method involves adding a titrant containing iodine to the sample until the reaction is complete. The endpoint is detected either visually or using an electrochemical sensor. This method is suitable for samples with higher water content.

- Coulometric Titration: In this method, iodine is generated electrochemically in situ from iodide. The amount of electricity required to generate the iodine is measured and used to calculate the water content. This method is more suitable for samples with very low water content (trace amounts).

Procedure

- Sample Preparation: The sample is prepared and placed in the titration cell.

- Titration: The titrant (for volumetric) or the electrochemical generation of iodine (for coulometric) is initiated.

- Endpoint Detection: The endpoint is detected when all the water has reacted with the iodine. This can be done visually or using sensors.

- Calculation: The amount of iodine used (or electricity in coulometric titration) is measured and used to calculate the water content.

Advantages

- High Accuracy: Capable of detecting very low levels of water.

- Versatility: Can be used for a wide range of samples.

- Speed: Provides quick results.

Limitations

- Chemical Interference: Some substances can interfere with the reaction.

- Sample Preparation: Some samples may require extensive preparation.

Moisture analysis of transformer oil is a critical aspect of transformer maintenance. By regularly monitoring and controlling moisture levels, operators can ensure the reliable and efficient operation of transformers, extending their service life and reducing the risk of failures. Employing accurate detection methods such as Karl Fischer titration and adhering to industry standards can help maintain optimal moisture levels and safeguard the performance of transformer systems.