Transformer Oil Testings

Regular transformer oil testing is a critical part of maintaining the reliability and efficiency of your power systems .

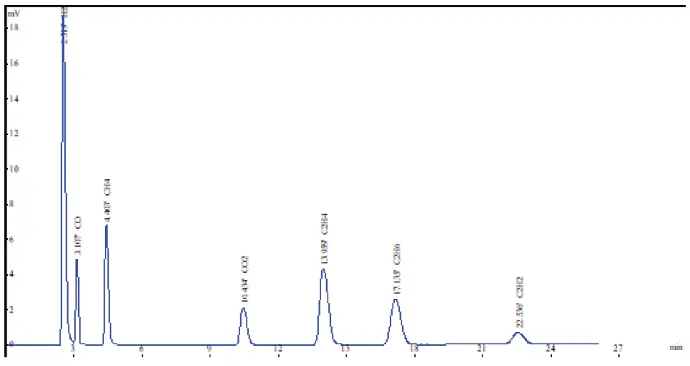

Dissolved Gas Analysis

ASTM D3612

Dissolved gas analysis (DGA) is a diagnostic test that examines the gas concentrations in transformer oil to help identify potential faults and prevent unplanned outages. The process involves taking a small sample of oil from the transformer, extracting the gases from the oil, and analyzing the gas mixture using gas chromatography (GC). The gas mixture is separated into individual chemical compounds, and the concentration of each gas is calculated and expressed in parts per million (pm).

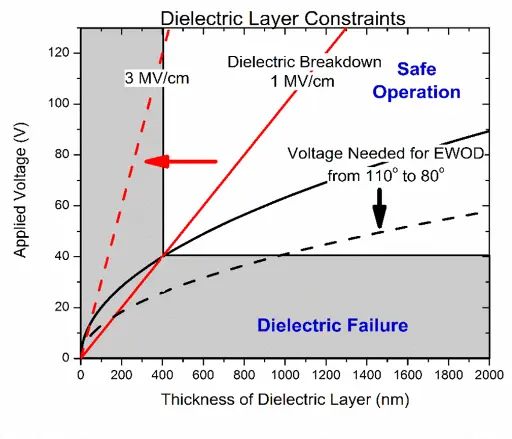

Dielectric Breakdown Voltage

ASTM D1816

Dielectric breakdown voltage is the voltage at which an insulating material, or dielectric, fails to prevent an electric current from flowing through it. When this happens, the material is no longer electrically insulating. The voltage required to cause dielectric breakdown can range from hundreds of volts to several kilovolts.

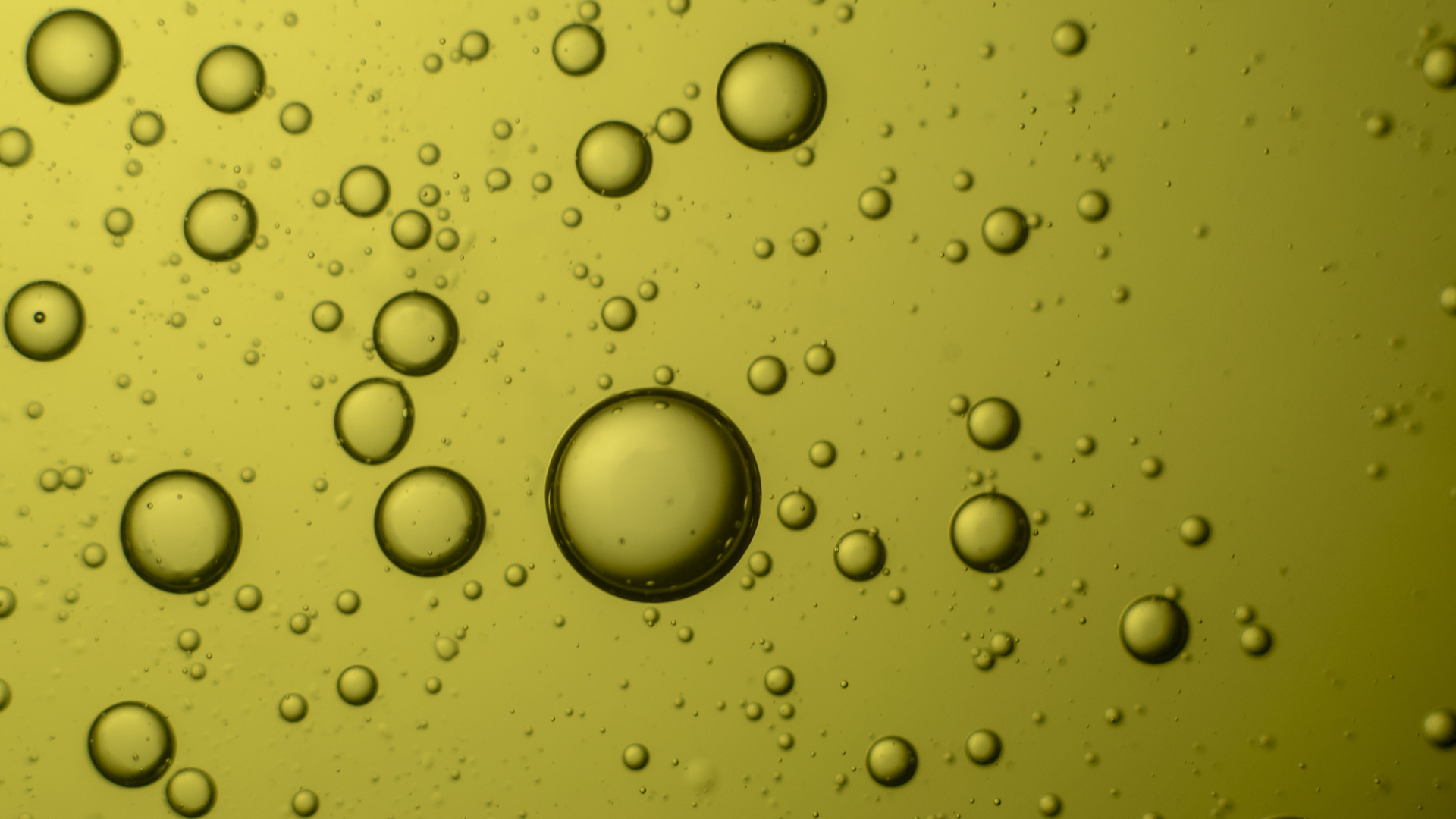

Visual Examination

ASTM D1524

Visual Examination of transformer oil is done by visually checking whether the transformer oil color is darkened, any particles are present in the oil, any emulsification or clouds are observed. Any of these observations is the symptom that the transformer oil is contaminated or aged.

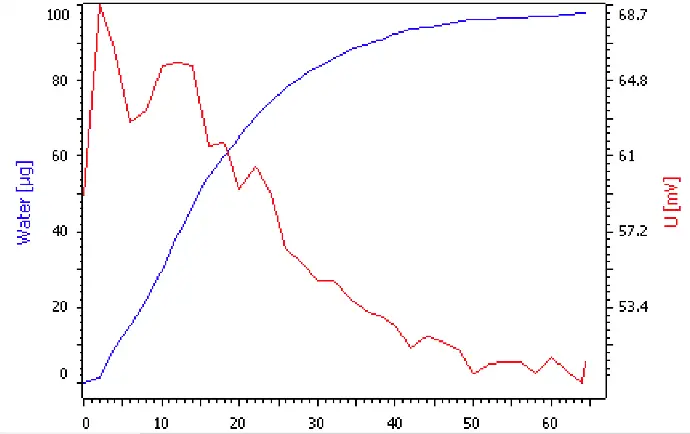

Moisture Analysis

ASTM D1533

Moisture in transformer oil can affect the transformer's electrical and mechanical strength, and can even lead to bubble formation. It's important to monitor the moisture content of transformer oil to ensure the transformer's efficiency and remaining lifespan.

The Karl Fischer Titration test is a common method for measuring the moisture content of transformer oil. This test measures the absolute amount of moisture in the oil, reporting the Parts Per Million (ppm) content. The test can measure all three states of moisture in the oil: dissolved, bound, and free water.

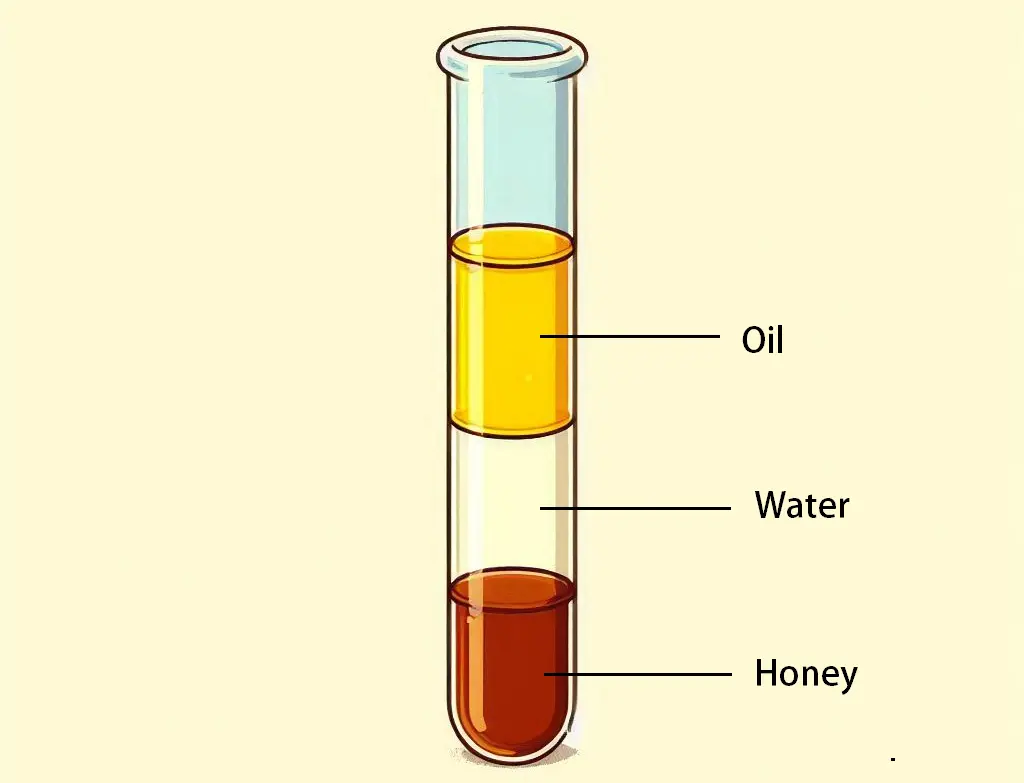

Relative Density (Specific Gravity)

ASTM D1298

Transformer oil has a relative density of around 0.895. Relative density, also known as specific gravity, is a comparison of the density of an insulating liquid to water, which has a specific gravity of 1.000. Since transformer oil is lighter than water, its specific gravity is less than one. A typical specification for new transformer oil is 0.84 to 0.91.

Relative density is a physical property that relates to the oil's composition and function, and it directly affects heat transfer. For example, lower density helps prevent ice from forming in the oil at subzero temperatures, which could lead to an electric breakthrough.

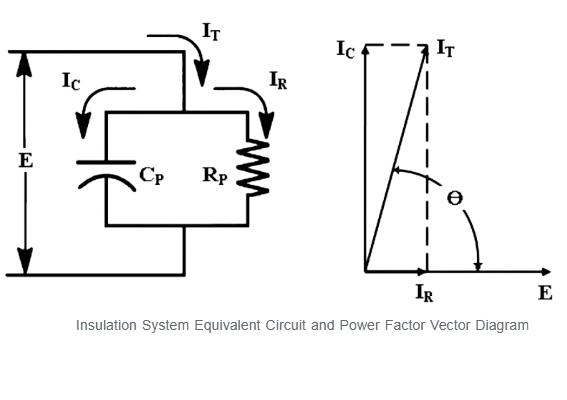

Dissipation Factor (Power Factor)

ASTM D924

The power factor of transformer oil is the ratio of true power to apparent power in an insulating oil. It's calculated as the cosine of the phase angle between the current and the AC voltage applied to the oil. Power factor is a diagnostic tool that can indicate the condition of a transformer's insulation system. It can also indicate the amount of dielectric loss and heating in the oil. A high power factor is an indication of significant power loss in the insulating oil, usually as a result of polar contaminants such as water, oxidized oil and cellulose paper degradation.

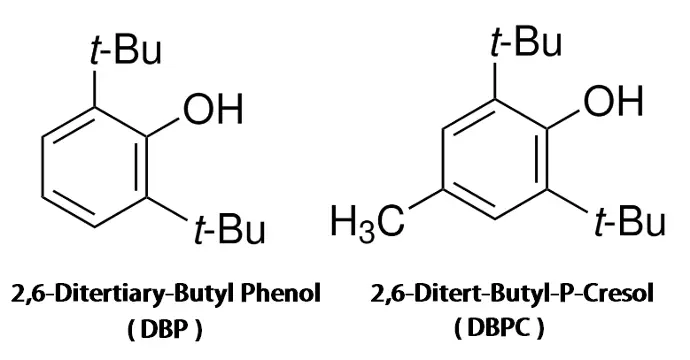

Oxidation Inhibitor Content

ASTM D2668

Transformer oils contain oxidation inhibitors to improve their resistance to oxidation and extend the life of the transformer. The amount of inhibitor in transformer oil varies depending on the type of oil. The oxidation inhibitor degrades as the oil ages. Fourier Transformed Infrared Spectrometer is used to measure the amount of the oxidation inhibitor in the oil.

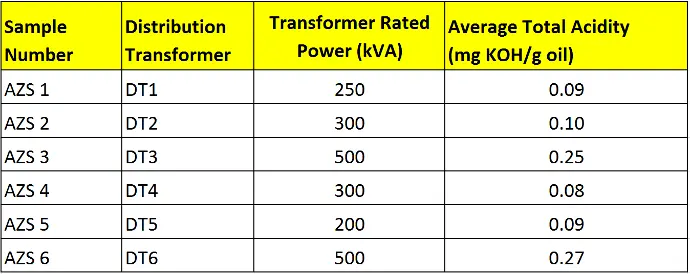

Neutralization Number

ASTM D974

The neutralization number, or acid number, of transformer oil is a measurement of the amount of acid in the oil, and is used to indicate the oil's condition. New transformer oil contains almost no acids, and results of 0.10 mg KOH/g of oil or less are considered good. As oil ages, it can become more acidic due to oxidation and contamination. An increase in acidity can indicate the rate of deterioration, and can lead to corrosion and sludge. The critical acid number is 0.25 mg KOH/g, and deterioration increases rapidly once this level is exceeded. To measure the neutralization number, potassium hydroxide (KOH) is added to a sample of oil to neutralize the acid. The amount of KOH required to neutralize one gram of oil is the neutralization number. For example, a neutralization number of 0.14 mg KOH/g means that 0.14 milligrams of KOH are needed to neutralize each gram of oil.

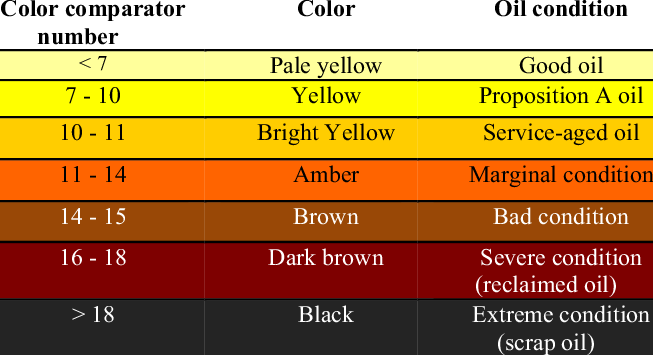

Color Testing

ASTM D1500

The color of transformer oil can change due to various factors such as oxidation, contamination, and aging. Fresh transformer oil is typically clear or light yellow. As the oil ages or becomes contaminated, it can darken, indicating potential issues. The oil sample is compared to a standard color scale using a color comparator device. This helps in quantifying the color change. Changes in color can be an early indicator of oil degradation or contamination. This helps in planning maintenance activities and oil replacement. Regular color testing ensures the transformer operates reliably and efficiently. Color testing is a simple yet effective way to monitor the condition of transformer oil and take necessary actions to maintain the transformer’s health.

Interfacial Tension

ASTM D971

Interfacial Tension (IFT) Analysis is a crucial test for assessing the quality and health of transformer oil. This test measures the tension at the interface between two immiscible liquids, typically transformer oil and water. The result is expressed in dynes per centimeter (dyne/cm). High IFT Values indicates good oil quality with minimal contamination. Low IFT Values suggest the presence of contaminants or degradation products, which can compromise the insulating properties of the oil.

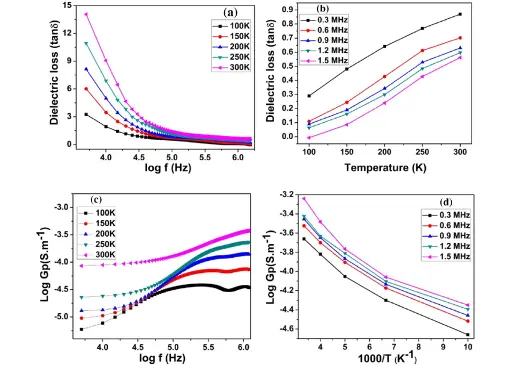

Resistivity

ASTM D1169

Dielectric loss is the energy loss in transformer oil caused by the hysteresis effect of dielectric conductance and dielectric polarization when an electric field is applied. The dielectric loss factor, or tan delta, is a parameter that measures the degree of dielectric loss and is expressed as the tangent value of the dielectric loss angle. It's an important indicator of the insulation performance of transformer oil and can be used to check for deterioration, sludge adhesion, and local defects.

Particle Count

ASTM D6786

Particle count measures the number and size of particles present in the transformer oil. These particles can include dust, dirt, metal wear particles, and other contaminants. The count is typically expressed as the number of particles per milliliter (mL) of oil. High particle counts indicate contamination, which can affect the insulating properties of the oil and lead to electrical failures. Analyzing the types and sizes of particles can help identify wear and tear in the transformer components, such as the core and windings. Regular monitoring of particle count helps in planning maintenance activities, such as oil filtration or replacement, to ensure the transformer operates efficiently and safely. The particles are counted by a device using light scattering or blockage techniques.